Most of your carpet suppliers claim they were part with the ROHS program for reduction and elimination of harmful materials. However, the total elimination of harmful substances might not be accomplished. Throughout an ISO-9001 inspection we did on a carpet factory thirty day period ago, discovered an undesirable set of chemical put to use for cleaning before shipping. The excuse they gave to do this atrocity was that they ran out of the regular cleaner they were using. Therefore they bought a good one from another supplier. We had to make a full investigation into the possibility, if they were this particular cleaner for all time productions. Fortunately, they were telling the true; however, because regulations, we close the factory.

My comment – Needless to say. The world is getting greener daily so should remind you with the ISO 14001 standard. I really believe and recommend to any business that it will take to implement the ISO 14001 usual to implement also this ISO 9001 certification consultants 9001 routine. You will find there’s big correlation in between your 2 leading. They actually support one other. It would be easier for organization to find out the ISO standard 14001 requirements if many experts have already certified for ISO 9001.

Champions could perhaps be to help perform their job with only a few days of . They are usually selected by an organization’s senior management, and they are generally pulled from a managerial act. They are tasked with choosing projects, defining goals, and providing focus to the other team members.

six sigma needs dedication or a willingness to full team. If there is not complete commitment chances are it won’t last go for walks . will stop being as successful as feasible. This is a method that is also long length. It is not just a change that is put forth then that’s this particular. Using this program those the boss of the project determine what needs in order to done to raise production subsequently ways enhance things. Compared to plan seem put in place, but this does not mean it operate or it will likely work months from soon. Everything is constantly being observed and somewhat improved. It is a way to up-to-date as well as always keeping focused on doing the most wonderful thing possible.

UK Ink Supplies is a mail order business perfectly located at the historic city of Lincoln, . They specialise in computer consumables ie. printer ink cartridges and laser toner printer ink cartridges plus printer paper. Because their name suggests UK Ink Supplies specialises in the production of recycled, compatible and original inkjet consumables for your own printer.

Now ought to be wondering how such institutes provide online education training, with no any face to face interaction. Well what these institutes do is their lean professionals develop the insulation material in this interactive form that a great an consideration in the student and learning becomes fun. For queries and doubts, the professors give their email address contact info to the scholars so that their query might be answered.

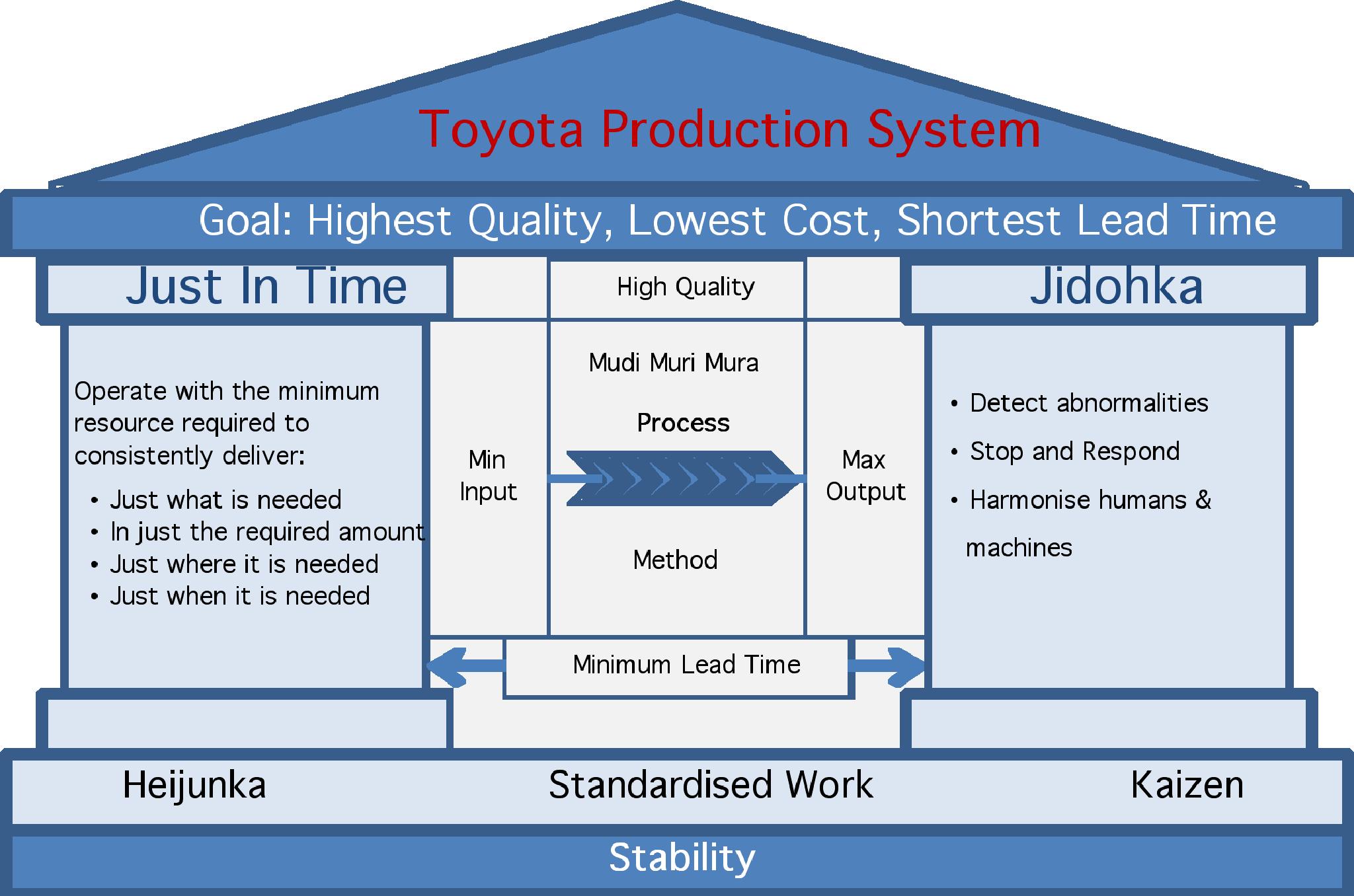

Just today I asked a associated with people why they thought Toyota had enjoyed as much success and growth. The solution was keep in mind their ISO 9001 certification consultants (TPS), lean manufacturing and attention to detail. That is exactly what General Motors came from your the Toyota / GM joint venture at NUMMI. Learn the TPS and we’ve solved our issues. And it’s exactly what most You.S. companies feel, that lean manufacturing, or Six Sigma or some other program can them fabulous.

Embrace the murkiness, messiness, and largeness. Document this method. By using a process map, in whichever form feels comfortable to you, you can record all these potential impacts, causes, risks, and sheer size. Recorded down on paper, distilled down to blocks and lines, a new clarity including a new perspective on what to do next will result.