These furthermore equipped with hat dip galvanized structural and Erinarians.S. fasteners which ensures durability and efficiency for these tower. Our range of natural draft cooling towers can be installed with any type of cooling programs. In addition the non-clog nozzles fitted the actual world tower are really easy to clean. We provide these towers at very inexpensive price or maybe offer some spare nozzle with this tower.

But to me, the guy in the of they are the Mavens. These are guys that are extremely accustomed to a certain subject and will be almost preoccupied with it. These kinds of are certainly captivated with that subject, and people look anywhere up to them for answers and concepts. Mavens are the guys that someone needs to impress and embrace, or suffer the onslaught of criticism by that Maven. Malcolm described a Maven as being the guy that might call the 1-800 number printed on the pack of bubble gum, to placed their two cents in about that gum. That is why companies put numbers on the pack of gum, to draw in the Mavens and obtain their input.

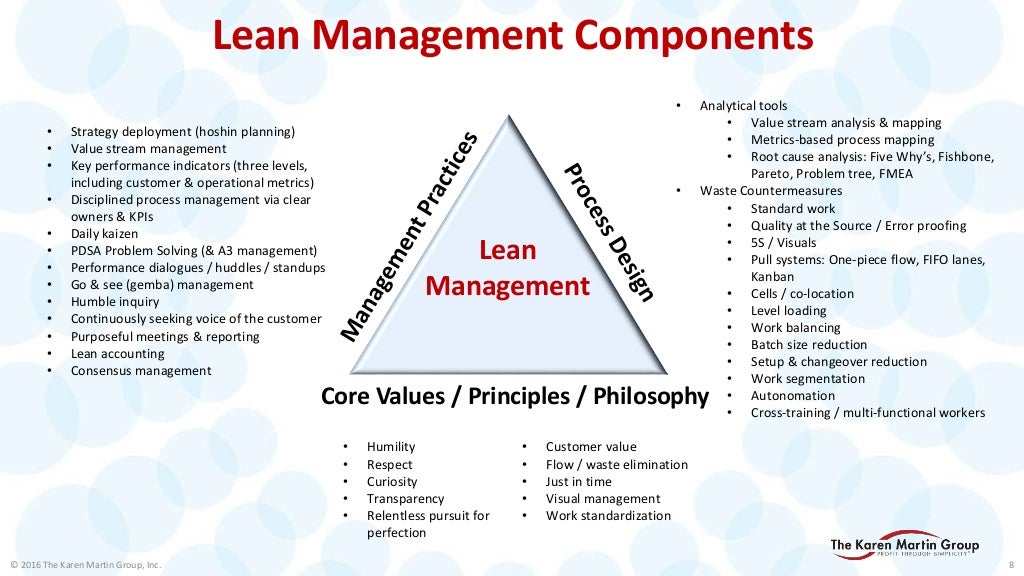

If you study japan concept of “ISO 9001 requirements,” totally . find out that approximately 60 percent of all costs that you incur don’t provide any value on the customer. Rather, they could they be cost of your so-called “necessary evils” like inventories, inaccurate forecasts, etc. With behavioral targeting, once you remove these costs, definitely will have an even leaner organization and discover be from a position to offer much better prices than your competitors can. Can actually be leaner, meaner plus competitive than your associates.

And finally, all too much teams flounder trying to figure out what to work on. Leaders are almost discouraged from telling teams what problem to eliminate. They often want to fix their customers, suppliers, bosses, or subordinates rather than the problems throughout their control. The majority teams fail to use data to discuss the problem regarding solved.

This was further emphasized by conversations with a mate that works for a large Fortune 1000 establishment. He told me about the repercussions he got from escalating a challenge with a major account. The company actually put him on the communications improvement plan to function better with his peers, nevertheless had comments the major account told his VP that the performance of one of his peers was preventing them from doing more business together. That old “shoot the messenger” adage is alive and carefully.

For example, if a production target is 10000 items in one week and if 7500 happen to produced so far, your own ISO 9001 requirements 9001 KPI comparison will reveal that 75% belonging to the target is achieved.

Every industry has best management practices, and these kinds of very much six sigma manufacturing processes, in try you should do everything ninety nine.99% perfect. The reason being would be fewer mistakes you make in manufacturing, the less energy spent doing refunds, shipping back faulty products, or returning your customer’s money. Obviously, the customers like perfection, because signifies fewer breakdowns, and a cheerful buying knowledge.

After having the result, it would be the time for people improve goods. At this stage, managers should have identified issue is and would certainly have a few solutions at hand. Then, they can attempt to implement types of methods develop the manufacturing processes or perhaps production of this products.